What is aluminum black anodizing?

Black aluminum anodizing is an electrochemical process that creates a protective oxide layer on the surface of aluminum parts, black anodic coating has a uniform, sleek black appearance. This process significantly enhances aluminum’s durability, corrosion resistance, and aesthetics, making it an ideal choice for various industries and applications. The anodized surface provides a stiff, wear-resistant finish, ensuring that the aluminum components can withstand the demands of their intended use.

The process of black aluminum anodizing

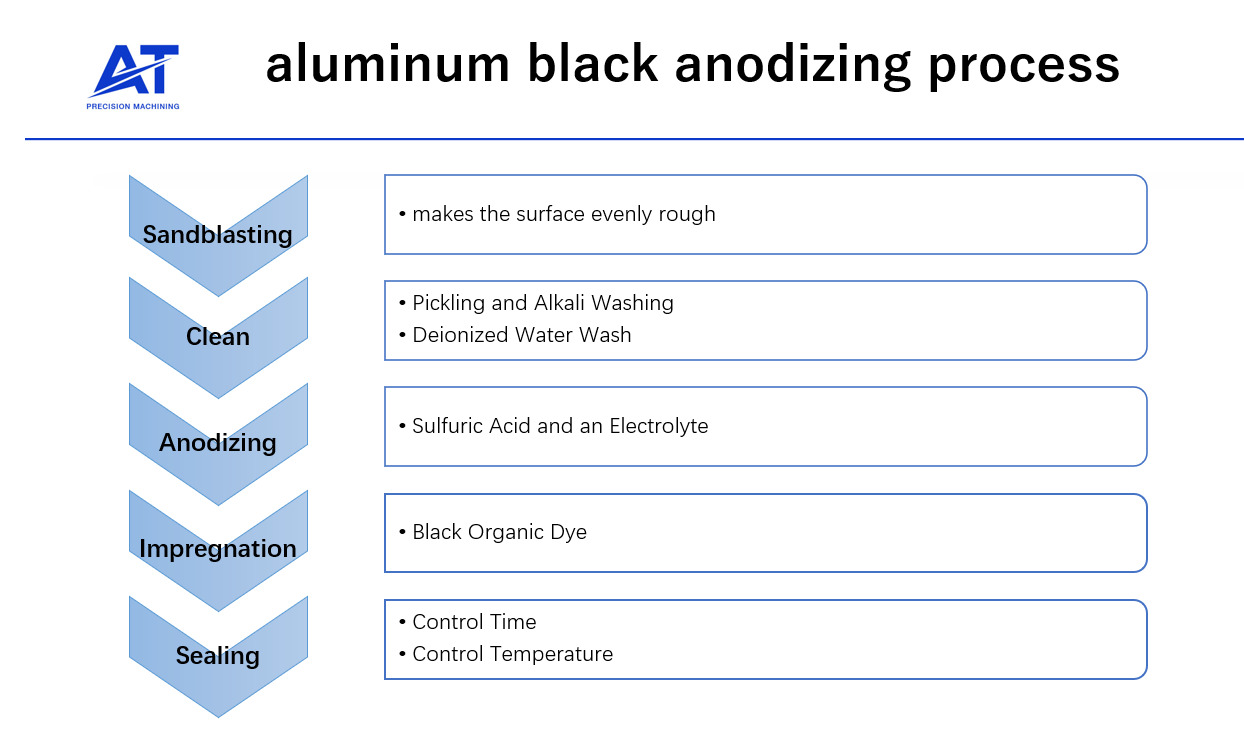

Key steps in the black aluminum anodizing process

Sandblasting makes the surface evenly rough, which helps create a consistent oxide layer during black anodizing. This leads to better color absorption and a uniform black finish on the part.

To start the black anodizing process, the aluminum surface is cleaned to remove dirt, oil, and impurities. This usually includes an alkaline and acid wash followed by a rinse with deionized water.

Once the surface is clean, the aluminum part is immersed in an electrolytic bath containing a mixture of sulfuric acid and an electrolyte. An electrical current is then applied, causing the aluminum to oxidize and form a porous layer of aluminum oxide.

This porous layer is then submerged in a black organic dye solution, penetrating the oxide layer and imparting the desired black color.

Finally, the dyed aluminum part is rinsed and sealed, typically by immersing it in boiling deionized water or a nickel acetate solution, to close the pores and lock in the color.

Sealing the anodized layer

Sealing the anodized layer is a crucial step in the black conversion coating process, as it enhances the Rust resistance and durability of the finished product. The sealing process closes the pores in the aluminum oxide layer, preventing dirt, moisture, and other contaminants from entering and compromising the integrity of the anodized surface. Sealing also helps to lock in the black organic dyes, ensuring a long-lasting, fade-resistant finish.

What types of black anodizing are available?

Type I (Chromic Acid Anodizing)

Type I anodizing, also known as chromic acid anodizing, is a process that utilizes a chromic acid electrolyte solution. This type of anodizing is typically used for applications requiring a thin, corrosion-resistant anodic coating layer. The resulting finish is not as wear-resistant or dark as Type II or III anodizing, making it less suitable for applications with a deep black finish.

Type II (Sulfuric Acid Anodizing)

Type II anodizing, or sulfuric acid anodizing, is the most common form and produces a thicker, more durable oxide surface layer than Type I. This process uses a sulfuric acid electrolyte solution, resulting in a more wear-resistant finish with improved corrosion protection. Type II anodizing can produce a range of colors, including black, depending on the dye used.

Type III (Hard Anodizing or Hardcoat Anodizing)

Type III anodizing, also known as hard anodizing or hard coat anodizing, is a process that produces an even thicker and more durable oxide layer than Type II anodizing. This process involves using a higher current density and lower temperatures in the electrolytic bath, resulting in a more complex, wear-resistant finish. Hard anodized aluminum parts are particularly suitable for applications requiring extreme durability, corrosion resistance, and wear resistance.

PTFE (Teflon) Impregnated Anodizing

PTFE-impregnated anodizing is a process where a layer of polytetrafluoroethylene (PTFE), commonly known as Teflon, is incorporated into the anodized surface. This process provides a low-friction, non-stick surface that is particularly useful in applications where reduced friction and wear are critical. PTFE-impregnated anodizing can be combined with black anodizing to achieve a black finish with enhanced performance.

Top Benefits of Choosing Black Anodized Aluminum for Your Products

Enhanced durability and corrosion resistance

Black anodized aluminum offers exceptional durability and corrosion resistance, making it suitable for various applications where longevity and performance are crucial. The anodized surface forms a protective barrier, preventing environmental factors such as moisture, chemicals, and UV radiation from damaging the underlying metal.

Improved aesthetics and visual appeal

Anodized aluminum’s sleek, uniform black finish gives products a modern, high-quality appearance. Black anodized parts have an attractive, professional look, making them an excellent choice for consumer products, industrial equipment, and automotive components.

Increased heat dissipation

Black anodized aluminum has improved heat dissipation properties compared to untreated aluminum. The anodized surface can absorb and dissipate heat more efficiently, making it an ideal choice for applications where thermal management is a concern, such as electronics and high-performance automotive components.

Reduced surface friction

Black anodized aluminum surfaces have a lower friction coefficient than untreated aluminum, resulting in smoother operation and reduced wear in applications involving moving parts. This reduction in friction can lead to increased efficiency and longer component lifespans.

Sam

The founder of AT-Machining has 30 years of CNC experience, dedicated to solving complex design and machining challenges for customers.

🔗 Best Practice for Black Anodized Aluminum

Bead-blast or uniform polish before anodizing; consistent grain ensures even dye absorption and color.

Key Factors to Consider When Black Anodizing Aluminum

Aluminum alloy selection

The choice of aluminum alloy can significantly impact the quality of the anodized finish. Some alloys are more suitable for anodizing than others, so selecting an appropriate alloy for your specific application is essential. Generally, aluminum alloys with higher purity tend to produce better anodizing results.

Anodizing bath parameters

Control of the anodizing bath parameters, such as the electrolyte concentration, temperature, and electrical current, is crucial for achieving consistent results. Proper management of these variables helps ensure that the anodized layer forms evenly and adheres well to the aluminum surface.

Temperature and current density control

The temperature and current density during the process of anodizing are critical factors that can impact the quality of the finished product. Higher temperatures and current densities result in thicker, more wear-resistant oxide layers. However, these variables must be carefully controlled to prevent overheating or excessive oxide layer growth, which can compromise the finish’s appearance and performance.

Time Considerations for optimal results

The duration of the anodize process affects the thickness of the anodized layer and the depth of the dye penetration. Longer anodizing times result in thicker oxide layers, increasing durability and Oxidation resistance. However, excessive anodizing times can lead to uneven coloring or a dull appearance, so it is essential to balance the process duration to achieve the desired results.

Max

Max is a technical sales expert with 10 years of engineering experience who has solved hundreds of complex technical difficulties and challenges for customers.

🔗 Best Practice for Black Anodized Aluminum

Do not mix aluminum alloys in assemblies requiring color matching, as different chemical compositions react differently during the anodizing process resulting in visible shade variations.

Overcoming Challenges in the Black Conversion Coating Process

Identifying and addressing common issues

Some common issues that can arise during the process of black anodizing include uneven coloring, streaks, or a dull appearance. These problems can often be attributed to improper cleaning and surface preparation, inconsistencies in the anodizing bath, or incorrect process control. To address these issues, it is essential to ensure that the aluminum surface is thoroughly cleaned and prepared, the anodizing bath parameters are properly controlled, and the process duration and conditions are optimized for the specific aluminum alloy being used.

Tips for consistent and high-quality results

It is essential to maintain strict control over the anodize process to achieve consistent and high-quality black anodized aluminum finishes. Some tips for ensuring optimal results include:

- Properly cleaning and preparing the aluminum surface to remove contaminants, oils, and impurities

- Using high-quality electrolyte solutions and dyes designed for black anodizing

- Controlling the anodizing bath temperature, current density, and duration to ensure uniform oxide layer formation

- Regularly monitoring and adjusting the anodizing bath parameters to maintain optimal conditions

- Sealing the anodized layer to lock in the color and enhance corrosion resistance

Maintaining proper process control

Proper process control is crucial for achieving consistent and high-quality black anodized finishes. This involves closely monitoring and adjusting the anodizing bath parameters, such as temperature, current density, and electrolyte concentration, as well as ensuring that the aluminum parts are adequately cleaned and prepared. Regular inspection and testing of the finished products can help identify any issues and make necessary adjustments to the process.

Tracy

Tracy is a sales manager with 18 years of experience in CNC machining, specializing in precision components and client solutions.

🔗 Best Practice for Black Anodized Aluminum

Specify anodize parameters on print: Type II or Type III, thickness range, sealing method, gloss level, color tolerance (ΔE), and conductivity needs; include rack locations to hide contact marks.

A Look at the Industries and Applications for Black Anodized Aluminum

Aerospace and automotive applications

Black anodized aluminum is commonly used in aerospace and automotive industries due to its lightweight, high strength, and excellent corrosion resistance. Components such as brackets, fasteners, and trim pieces can benefit from the enhanced durability and visual appeal of black anodizing.

Consumer Electronics and Appliances

The sleek, modern appearance of black anodized aluminum makes it an ideal choice for consumer electronics and appliances. Products like smartphones, laptops, and kitchen appliances often feature black anodized aluminum components for visual appeal and improved performance.

Sporting goods and outdoor equipment

Black anodized aluminum is widely used to manufacture sporting goods and outdoor equipment, such as bicycles, camping gear, and firearms. Anodized aluminum’s corrosion resistance, durability, and lightweight nature make it a popular choice for these applications.

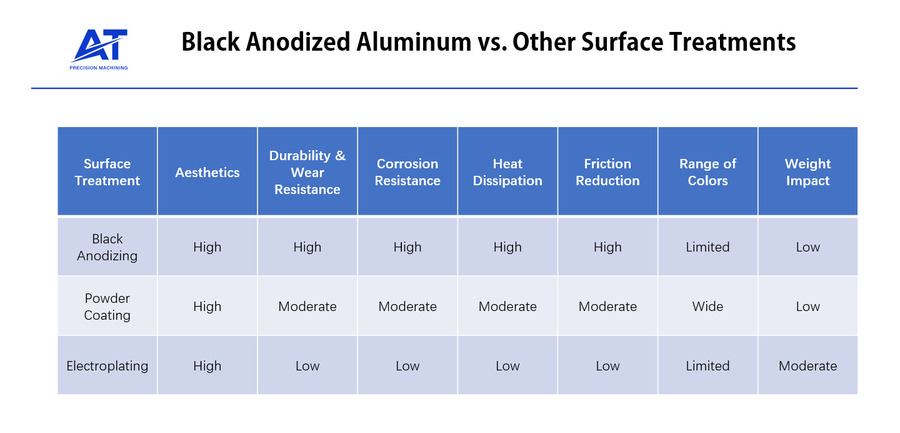

Black Anodized Aluminum vs. Other Surface Treatments: A Comparison

What better way to show the contrast than this chart?

Learn more about the comparison between anodizing and Powder Coating

Conclusion

black anodized aluminum offers a unique combination of exceptional aesthetics, impressive durability, and outstanding performance characteristics. This comprehensive guide has provided valuable insights into the black anodizing process, its benefits, and comparisons to other surface treatments like powder coating and electroplating.

For those seeking a stunning and durable finish for their aluminum products, black anodizing stands out as an ideal choice. AT-Machining‘s commitment to quality and customer satisfaction ensures that you receive the best possible results, elevating your product’s performance and appearance. Trust AT-Machining for all your CNC machining and surface finishing needs, and experience the difference that our expertise and dedication to excellence can make for your projects.