Nowadays, there are numerous finishing processes or methods in practice. Therefore, manufacturers have diverse options to choose from now. Bead blasting sits at the top of the list of these finishing techniques.

While there are several media blasting techniques, bead blasting offers several advantages to manufacturers. Despite its many benefits, there are some downsides to it as well. Therefore, it is essential to understand how the bead blast finish works.

This article will discuss everything you need to know about bead blasting finish. In addition, you will get an insight into the right materials suitable for bead blasting and, most importantly, how this finish is applied.

The information shared will assist you in getting the best results from the bead blast finish. So let’s get right to it!

What is Bead Blasting?

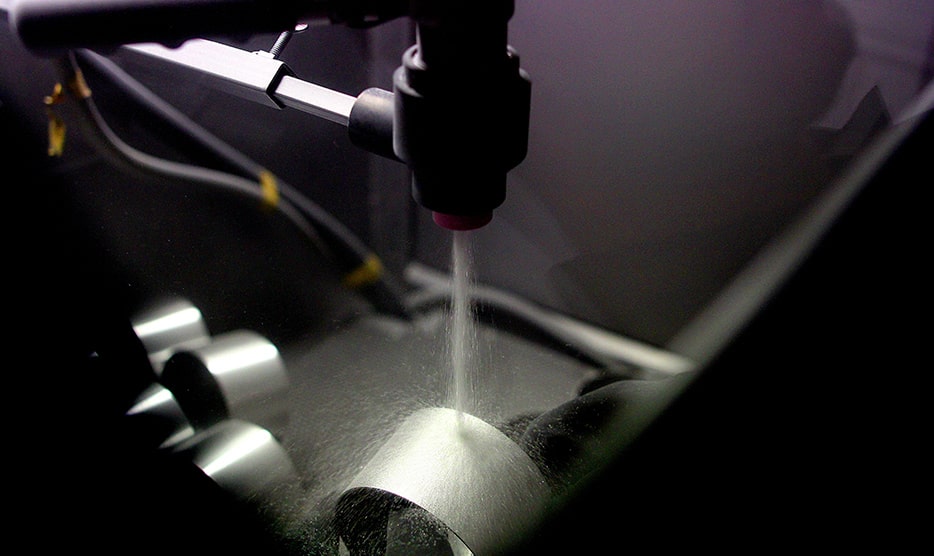

The term bead blasting is one of the many surface finishing techniques of product manufacturing. A bead blast finish is an operation that has to do with moving or throwing blast media or abrasive material against a surface to give it a desirably smooth surface finish.

This process involves cleaning or giving a product a finishing touch to make it smooth. The name ‘bead blasting’ is often used with numerous blast operation names like grit blasting, abrasive blasting, soda blasting, and shot blasting.

A more precise definition of ‘bead blasting’ explains it as a process that involves using glass beads to change the form of the substrate structure.

How Does Bead Blasting Work?

Bead blasting involves throwing bead-shaped or sphere media against a substratum. Aluminum, stainless steel, or any other material that needs a surface finishing via blasting is suitable for use.

Often, a significant amount of abrasive blasting is performed using unevenly cut or rough media and leaves a gritty surface finish. Bead blasting utilizes round spherical media that gives a smooth, uniform finish after being impinged against the surface of a component.

In addition, steel shot blasting in this process permits flexible conditioning of the available substrate. Manufacturers use the bead blasting technique when there is a need for smooth and even finishes. Some people also prefer this technique for parts intended to possess a satin finish that is not sharp.

The bead blast finish allows manufacturers to obtain a quality surface finish that is unrefined but dependable. The fine glass beads are most effective on aluminum parts that require a satin finish. The coarse glass beads give a regular rough finish as they cover any defects in the substrate surface.

Several other materials will make any substrate it collides with even darker, giving it a greyer finish. Materials such as silicon carbide, garnet, or aluminum oxide possess ideal grits. Meanwhile, glass bead blasting permits the substrate to retain its elementary color, giving a polished surface finish.

The Pros and Cons of Bead Blasting

A bead blast finishing touch earns your custom machining part a clean, smooth, attractive surface. Bead blasting can be applied to various materials, including titanium, aluminum, stainless steel. Also, soft metals such as copper, brass, and plastics are not left out.

Despite the many advantages of this process, it also has some drawbacks. In this section, we will discuss the pros and cons of the bead blasting process.

Pros of Bead Blasting

Bead blasting has an array of advantages that you should keep in mind. Here are some of the benefits that you should familiarize yourself with:

- Bead blasting does not alter the elementary color of a part. As a result, the bead-blasted surface is brighter and more pleasing.

- Bead blasting is cost-effective, affordable, and serves less aggressive surface finish options.

- Bead blasting is one of the most environmentally friendly manufacturing processes.

- It is a safer blasting option when compared to other techniques.

- The bead blast technique is the perfect option for delicate or fragile components.

- Bead blasting gives room for recycling before replacement, with the change to recycle glass beads up to 30 times.

Cons of Bead Blasting

While there are several advantages to using bead blasting, the following drawbacks may limit its use:

- Bead blasting may not be strong enough for steel materials

- It may take a longer time to smoothen hard materials or surfaces.

- Glass beads do not give room for additional painting because of their lack of profile.

- Bead Blast finish often needs a trained and skilled operator, and it must be a manual operation. Therefore, the results of your bead blasting project lie solely on your operator’s skill.

Applications of Glass Bead Blasting Finish

Bead blast surface finish helps manufacturers gain an accurate surface finish. This is done without hindering the component’s dimensions. Although this process is a simple and easy one, it is less aggressive when compared to other media.

Likewise, it does a perfect job on numerous materials such as aluminum, steel, titanium, copper, etc. This way, it makes it a very suitable media for multiple industrial applications. In addition, many manufacturers employ a bead blast surface finish to improve the durability of their parts.

The bead blasting finishing process is flexible such that it fits perfectly well into a large number of manufacturing processes. Bead blast media comes in different measures or sizes. Tiny glass beads facilitate a lighter operation requiring nicely detailed work as it serves the desired finish.

On the other hand, average-size glass beads are the best option for aluminum and stainless steel materials. This is because they are famous for hiding errors on part surfaces.

Large glass beads are best for removing debris. They give relatively rough surfaces in a blast. Thus, you can employ them on metal molding and automotive components.

Parts that May Require Bead Blast Finishing

Many components may need a bead blast finish. Among them are:

- Aircraft parts before painting them.

- Automotive parts that require adding brand new painting.

- Aluminum materials used for medical equipment.

- Firearms and other military gear.

What Are the Specific Uses of Bead Blasting?

The bead blasting process is useful for a vast number of purposes, namely:

- Deburring

- Peening: This is peculiar to firearms. It helps to avoid metal cracking and prevent fatigue.

- Cosmetic finishing

- Applying polish to materials such as cast iron, stainless steel, and aluminum

- Extracting calcium deposits, paint, scale, and rust.

Bead Blast Finish with AT Machining

Applying a bead blast finish to your parts can earn it a smooth and brighter surface finish. It gives it a cosmetic finishing to improve its overall appearance, texture, and durability.

However, letting unqualified hands handle your projects may prove unproductive. As a result, it is crucial to look out for well-grounded experts with years of experience. Such a manufacturing partner must serve a perfect combination of highly skilled professionals and top-quality manufacturing techniques.

AT Machining is at your disposal to handle product surface finishing to your satisfaction. We boast excellent years of experience in this field and deliver cost-effective surface finish for a wide range of industries.

We offer best-in-town bead blasting services as well as other surface finishing techniques. Our trained technicians deliver adequate services as they work with you to create custom metal finishing. This way, you are sure of desired surface finish results that match your requirements.

We put our customers first at AT Machining. Thus, we make it our priority to satisfy you at all times. All you need to do is contact us or send in your design file to get an instant quote. We are always ready to work with you!

Conclusion

Bead blasting is a flexible and eco-friendly part finish procedure. Glass beads give your parts the top-notch finishing touches they need, making them clean, smooth, and more aesthetically pleasing.

The bead blasting method is an excellent alternative to other abrasive blasting methods since it is not an aggressive type. Contact AT Machining today for high-quality bead blasting and custom machining services. We look forward to having you!

FAQ

Is Bead Blasting Finishing Expensive?

Glass bead blasting is relatively inexpensive and produces an excellent result. Glass beads are cheap to produce and can be reused 30 times or more. This proves how cost-effective this process is.

Can AT Machining Bead Blast Aluminum?

Yes, we can. The machined aluminum parts end up with machining marks on the surface. Glass Beads Blast will produce a smooth, uniform, and matte finish. However, medium-sized beads get the job done when blasting aluminum. These beads help to conceal all imperfections on the aluminum part surface.