The Benefit of CNC Machining Motorcycle Parts

Definition and Explanation of the CNC Process

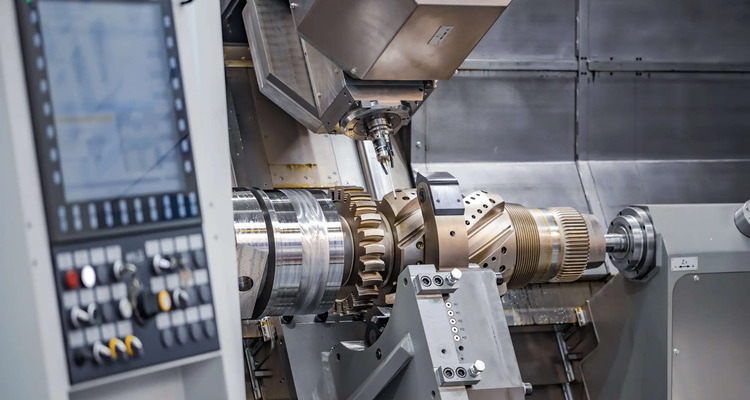

CNC (Computer Numerical Control) machining is a process where pre-programmed computer software directs the movement of factory machinery and tools. It can easily control complex machinery like grinders, mills, routers, and lathes.

Advantages of CNC Machining for Motorcycle Parts Customization

In motorcycle customization, CNC machining stands out as a game-changer. This advanced technology brings many advantages to the table, making it a go-to method for bike enthusiasts and professionals alike. The beauty of CNC machining lies in its precision, versatility, and efficiency, enabling an unprecedented level of customization that was once out of reach. But that’s just the tip of the iceberg.

Let’s delve into motorcycle parts customization through CNC machining, a process that’s revolutionizing how we personalize our rides. As we explore the numerous benefits, from enhanced precision to distinct aesthetics, you’ll discover how CNC machining can elevate your motorcycle parts customization experience. Buckle up and prepare for an exciting journey into next-level motorcycle personalization.

Precision and Accuracy

CNC machining provides high precision and consistency, even for complex or intricate designs. This means you can replicate any design flawlessly time after time.

Versatility

CNC machining can work with various materials, from metal and plastics to ceramic. This flexibility allows you to choose the perfect material for your needs and preferences.

Speed and Efficiency

Automated technology allows CNC machining to produce parts quickly, often more efficiently than manual machining. This means you can get your customized motorcycle parts faster and return on the road sooner.

Customizability

With CNC machining, you’re only limited by your imagination. You can create bespoke parts that express your style and enhance the performance and comfort of your motorcycle.

Durability

CNC-machined parts are typically more robust and durable than their manually machined or mass-produced counterparts. They can withstand the rigors of motorcycling, providing a long-lasting solution for customization.

Cost-effective

While the upfront cost can be higher than off-the-shelf parts, the longevity and personalization that CNC machined parts offer can provide better value in the long run.

Improved Performance

Custom CNC machined parts can be designed to improve the performance of your motorcycle. Whether it’s lighter-weight components for better handling or customized gears for smoother performance, CNC machining can make a significant difference.

Popular CNC Motorcycle Parts

Popular CNC Motorcycle Parts customized using advanced CNC machining techniques include engine casings, handlebars, foot pegs, brake and clutch levers, sprockets, and even bespoke chassis components. With the power of CNC machining, these motorcycle parts can be tailor-made to provide unique aesthetics and improved performance attributes, truly setting your ride apart from the rest.

Engine Casings

CNC machining allows for the creation of unique engine casings, which protect the engine and add aesthetic appeal to the bike. These can be customized with intricate designs or logos.

Handlebars

Custom handlebars can improve the bike’s ergonomics, making riding more comfortable. CNC machining allows for precise handlebar shape and size adjustments to fit the rider’s preference.

Foot Pegs

With CNC machining, foot pegs can be tailor-made to the rider’s foot size and riding style, enhancing grip and control.

Brake and Clutch Levers

Custom brake and clutch levers can improve the feel and responsiveness of the bike’s controls. They can also be designed to match the aesthetic theme of the bike.

Sprockets

CNC machined sprockets can offer improved performance and durability. They can be customized for specific riding conditions, such as off-road or high-speed racing.

Chassis Components

Bespoke chassis components, like brackets or mounts, can be produced through CNC machining. These are not only functional but can also add a unique look to the bike.

Exhaust System

A custom exhaust can change the bike’s look, sound, and performance. CNC machining allows for intricate design work on exhaust headers and mufflers.

Motorcycle Wheels

Custom motorcycle wheels can transform a bike’s appearance and handling characteristics. With CNC machining, it is possible to produce unique and precise designs for stylish and performance-oriented wheels, allowing for endless possibilities in customizing motorcycle wheels.

Fuel Tank

A custom fuel tank can give the bike a distinctive look. With CNC machining, tanks can be made to fit the bike perfectly and customized with unique designs.

Seat

While primarily done for comfort, a custom seat can also drastically alter a bike’s aesthetics. CNC machining can be used to create custom seat mounts and brackets.

Wide Range of Materials Suitable for Motorcycle CNC Machining

CNC machining is incredibly versatile, capable of crafting a wide range of CNC Machined Motorcycle Parts from various materials. This includes sturdy metals like aluminum, stainless steel, titanium, brass, and various plastics. With such flexibility at your fingertips, the possibilities for designing and customizing your CNC Motorcycle Parts are virtually limitless.

Aluminum

Aluminum alloys are popular for CNC machining motorcycle parts due to their lightweight, strong, and corrosion-resistant properties. These alloys are well-suited for parts like engine casings, handlebars, and footpegs, where durability and strength are crucial. Additionally, the lightness of aluminum alloys can help improve a motorcycle’s overall performance and handling.

Stainless Steel

Stainless steel is extremely durable and resistant to rust and corrosion, making it a great choice for parts exposed to the elements or high-stress components like sprockets and exhaust systems.

Titanium

Titanium’s high strength-to-weight ratio makes it popular for high-performance motorcycle parts such as exhaust systems and engine components. While more expensive, titanium’s added strength and lightness make it a worthwhile investment for those looking for durable, lightweight motorcycle parts.

Brass

Brass is easy to machine and has a unique aesthetic appeal. It’s often used for small decorative parts or components like badges or trim pieces.

Copper

While not as commonly used due to its softness, copper can be utilized for specific parts like electrical components and decorative elements due to its excellent electrical conductivity and unique color.

Carbon Fiber

Recent advancements in CNC machining allow for the use of carbon fiber in custom parts for motorcycles. Although not a traditional material for CNC machining, carbon fiber’s lightness and strength make it ideal for performance-enhancing components such as body panels and certain structural parts. As a result, custom CNC machined carbon fiber parts have become increasingly popular among motorcycle enthusiasts looking to improve their bike’s performance and aesthetic appeal.

Plastics (e.g., ABS, Polycarbonate, Acrylic)

CNC machining can also work wonders on tough plastics like acrylic to produce high-quality parts such as windshields, light covers, and motorcycle bodywork. These plastic materials are lightweight, highly durable, and impact-resistant, making them ideal for motorcycle lights consisting of covers, lenses, and reflectors. At our CNC machining service, we possess the necessary expertise to work with a wide range of plastic, including tough plastics like acrylic, to deliver parts that meet your specific requirements.

Delrin/Acetal

This is a tough, wear-resistant plastic often used for creating prototypes or parts that require high stiffness and low friction, such as bushings or small moving parts.

Ceramics

With their heat resistance and durability, Ceramics are making their way into custom motorcycle parts. From high-temperature components and brake systems to bearings and decorative elements, ceramics offer unique advantages that can enhance the performance and aesthetics of motorcycles.

CNC Machining Techniques for Motorcycle Parts Customization

CNC Milling

CNC milling is a crucial technique in machining motorcycle parts, particularly when precision and complexity come into play, such as with motorcycle engine parts. In CNC milling, the workpiece is stationary while the cutting tool rotates and moves along various axes to remove material.

This process allows for creating complex geometries and intricate details that would be challenging with other techniques. Whether it’s crafting complicated motorcycle engine parts to boost performance or creating unique, custom components to enhance aesthetics, CNC milling provides the accuracy and versatility needed for high-quality, customized motorcycle parts.

CNC Turning

CNC turning is a critical technique in customizing motorcycle parts, especially when creating precision parts like motorcycle wheels and engine components. This process involves rotating the workpiece while a cutting tool moves linearly.

This method is perfect for creating symmetrical parts, allowing for high accuracy and consistency. So whether you’re crafting bespoke motorcycle wheels for optimal handling or precision-engineered motorcycle engine parts for peak performance, CNC turning offers the precision and consistency you need to take your ride to the next level.

Laser Cutting and Engraving

Laser cutting and engraving techniques have become a go-to for creating unique custom parts in the motorcycle world. Laser cutting employs a high-powered laser to cut exact shapes and designs from various materials, offering unparalleled precision. Laser engraving, on the other hand, allows for adding personalized text, logos, or intricate designs onto the surface of the parts, giving your motorcycle that personal touch.

These techniques open up a world of customization, allowing riders to put their unique stamp on their machines, both in form and in function.

Perfect Motorcycle Parts Surface Finishes

Polishing and Deburring

Polishing is vital in finishing parts like motorcycle fuel tanks or fenders, where a smooth and shiny surface is desirable. It creates a lustrous finish that enhances the part’s aesthetic appeal. Deburring, on the other hand, is commonly applied to machined parts like gear components, removing any ‘burrs’ or rough edges left after the machining process. This makes the part safer and ensures its proper function within the motorcycle’s mechanical system.

Anodizing

Anodizing is an electrochemical process commonly used to treat aluminum parts such as handlebars or wheel rims. Hard anodizing creates a thicker oxide layer, increasing corrosion resistance, better adherence to paint primers, and improved aesthetics. Hard anodizing is particularly useful for engine parts exposed to harsh environments. Anodized motorcycle parts are also durable and available in various colors, allowing for a personalized touch.

Powder coating

Powder coating is a highly durable finishing process commonly used for motorcycle parts like frames, swingarms, and engine guards. The technique involves applying a dry powder electrostatically, then curing it under heat to create a long-lasting finish. Powder-coated motorcycle parts are highly resistant to chipping, scratching, and fading, making them ideal for harsh conditions where durability is essential.

Bead blasting

Bead blasting is often used on metal parts like engine casings or exhaust pipes, providing a satin or matte finish. By propelling fine glass beads at the part’s surface, bead blasting removes surface deposits and provides a uniform, non-reflective surface that can hide imperfections and reduce glare.

Electroplating

Electroplating is a process that applies a metal coating to a part, frequently used on motorcycle parts for both protection and aesthetics. Chrome or nickel electroplating, for example, can be found on parts like exhaust pipes, handlebars, and decorative trim, offering a shiny, mirror-like finish and enhanced corrosion resistance.

Uv-resistant Surface Treatment

UV-resistant treatments are essential for plastic parts regularly exposed to sunlight, such as windshields, fairings, or saddlebags. These treatments protect against color fading and material degradation caused by UV radiation, preserving the parts’ appearance and structural integrity.

Tips for a Successful Motorcycle Custom CNC Machining Project

Choosing the Right CNC Shop or Machinist

When choosing the right shop for creating your CNC Motorcycle Parts, prioritize those with a solid reputation, extensive experience in motorcycle part customization, and top-notch customer service. They should be able to bring your designs to life and offer valuable insights based on their expertise, ensuring your CNC Motorcycle Parts meet your expectations and elevate your biking experience.

Collaborating Effectively With Professionals

Clear and consistent communication is paramount when collaborating on your CNC Motorcycle Parts project. Articulate your expectations accurately, remain receptive to their expert advice, and set a definitive timeline for project completion. Regular updates and check-ins can help keep the project aligned with your vision, ensuring that the result – your bespoke CNC Motorcycle Parts – meet or exceed your standards.

Budgeting and Time Management

Crafting custom motorcycle parts through CNC machining can be a substantial investment, so it’s crucial to budget accurately. Ensure you account for potential cost overruns or adjustments during the machining process. Equally important is time management. Custom motorcycle parts projects often take longer than purchasing off-the-shelf solutions. Therefore, carefully planning your project timeline can help avoid disappointments and ensure a smooth customization journey.

Conclusion

Embracing CNC machining to customize motorcycle parts can distinguish your ride uniquely. This process involves understanding CNC’s benefits, identifying popular customization parts, selecting appropriate materials, and exploring various machining techniques and finishes.

AT-Machining, a frontrunner in providing CNC Machining Services in China, excels in the field of motorcycle parts customization. Leveraging the prowess of cutting-edge CNC machines, we skillfully manipulate a wide array of materials, from metals and plastics to ceramics, to create your desired motorcycle parts.

Our proficiency in assorted finishing techniques such as nitriding, plating, and anodizing further empowers us to fabricate robust and aesthetically pleasing parts. Our steadfast dedication to quality and customer satisfaction truly sets AT-Machining apart as a trusted name in the CNC Machining Service sector for motorcycle parts.

Ready to turn your motorcycle customization vision into reality? Contact AT-Machining today! Let’s collaborate to create your dream ride with our high-quality CNC machining and finishing services. The journey to a unique ride starts here!